About Lealso

Dongguan Lealso International Sex Toys Co., Ltd.

Looking for a reliable ODM and OEM manufacturer for sex toy? Look no further! Our factory is located in Chang’an Town, Dongguan City, covering an area of over 3000 square meters. With a team of over 100 employees, we are able to meet our customers’ exclusive customization needs and ensure fast delivery.

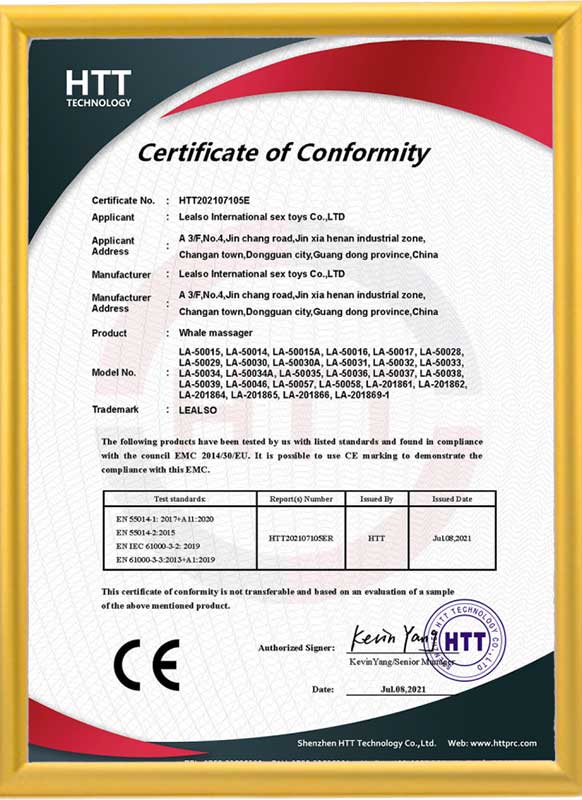

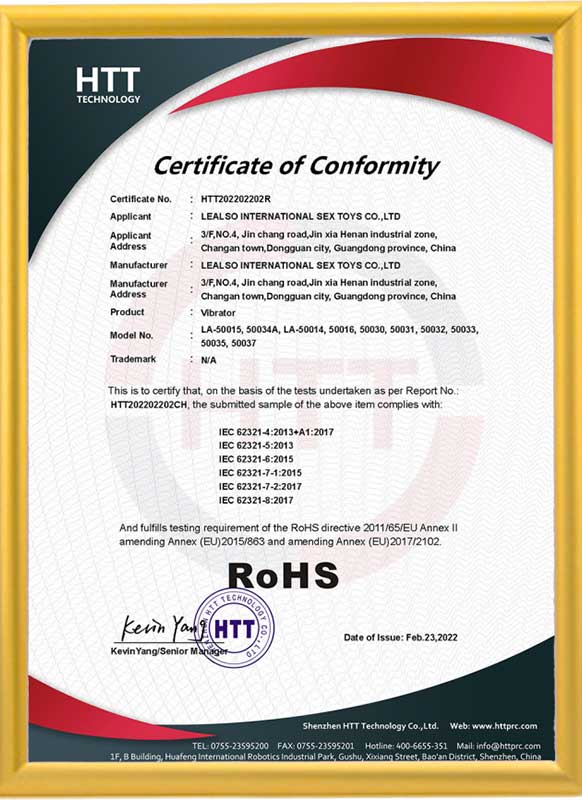

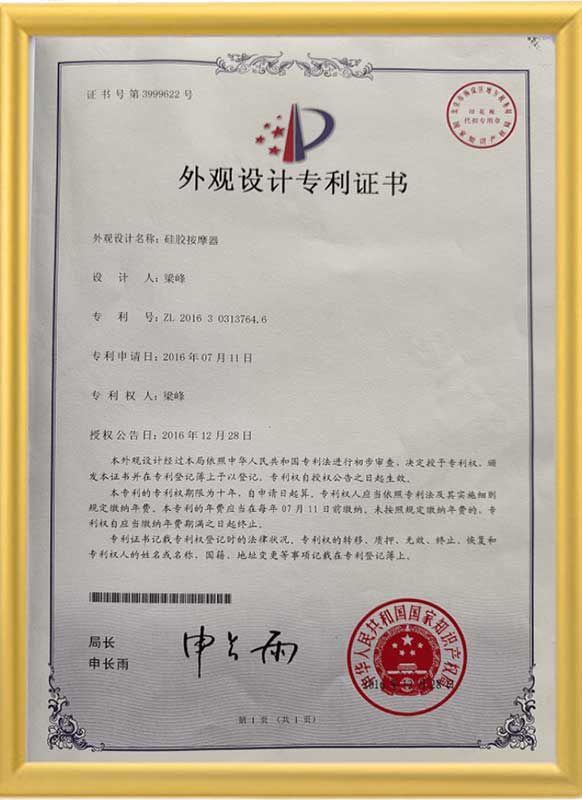

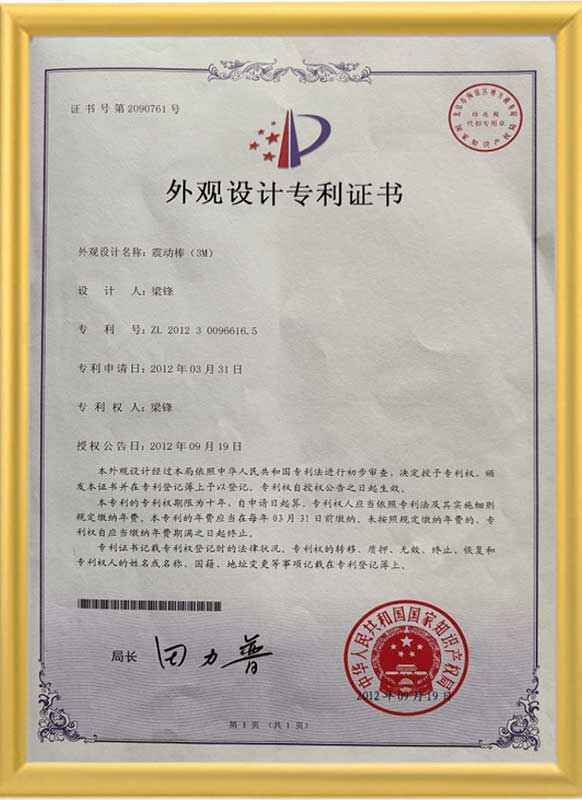

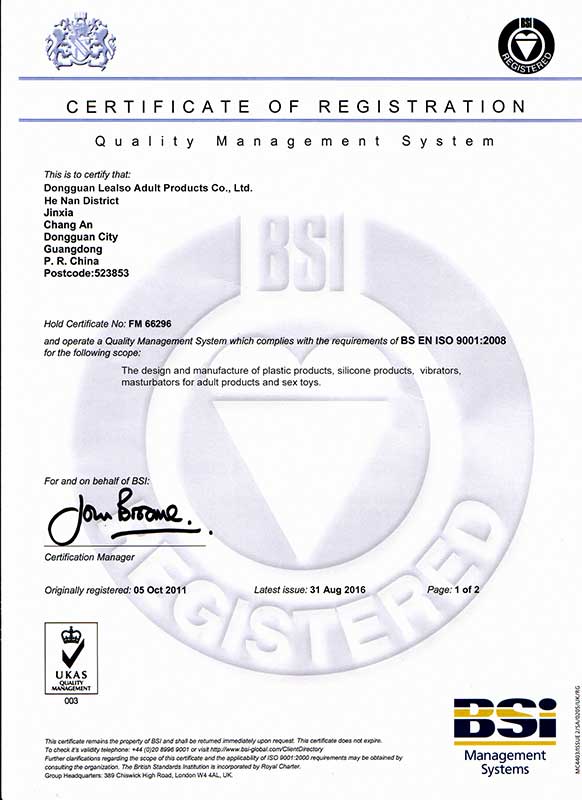

Our Certificates

Lealso Adult product manufacturing steps

Precision Silicone Cutting: Key Steps for Ensuring High-Quality Products

In the silicone cutting process, tools such as cutting machines and various techniques are commonly employed to ensure precise cuts and maintain high-quality silicone products.

These tools are chosen based on the shape and requirements of the silicone products, providing the necessary precision. Key cutting techniques include straight cutting, rotational cutting, and water jet cutting, aiming to minimize the risks of damage and fragmentation. It is crucial to ensure that the silicone products are fully cured before cutting, as this is a prerequisite for accurate cutting and maintaining the overall quality of the products

Surface Oil Spraying Treatment

Utilizing specialized spraying equipment like spray guns or sprayers, uniformly apply lubricants or coatings onto the surface of silicone products. Ensure an even distribution of the coating to prevent uneven thickness or the formation of bubbles. Silicone spraying serves two main purposes:

- Elevated Tactile Comfort: The application of oil enhances the tactile comfort of silicone products, creating a distinctive ink layer on the surface that offers an exceptionally comfortable touch experience.

- Static Electricity Prevention and Dust Resistance: The primary objective of spraying silicone products is to counteract static electricity, thereby achieving an effective dust-resistant outcome. Given that silicone material exhibits low anti-static capability due to its inert nature, the process aims to address the susceptibility of silicone products to dust and dirt accumulation.

Lealso Advantages

Modeling design

From the client's idea to the final design, it is a challenging and creative journey. Through close collaboration, creative thinking and continuous feedback, we turn our customers' visions into reality and create unique and compelling adult toys. The process requires a blend of patience, communication and inspiration, but the end result will exceed customers' expectations and bring unlimited value to their brands and businesses.

structural design

our engineers use computer-aided design software to model and render for virtual testing and improvement during the design phase, ensuring that the internal structure and mechanical parts of the product work perfectly together, while the rational stacking of the internal parts of the product makes the product safe, durable and superior in performance.

electronic design

our engineers design circuit boards including sensors, batteries, switches, components and control ics, etc. They use electronic design software for circuit design, simulation and simulation to ensure the performance and stability of the toy's electronic system. They also need to consider power management, security and compliance with relevant regulations.

Lealso-Company Display

Our core competitive advantage lies in quality control from the source, including exterior design, mold manufacturing, material selection, injection molding, product assembly, testing, packaging, and export transportation. We strive to meet high-quality standards for each product. Every production process undergoes strict monitoring to reduce manufacturing costs and make our products highly competitive in the market.

FAQ

What’s The MOQ?

Basically, NO MOQ For Most Products, Trail Oeder, Or Sample Order Will Be Acceptable

Quality Warranty?

Most Of Our Products Are With 6 Months Quality Warranty

Should We Use Our LOGO/Brand?

Customized Logo For Products Or Package Will Be Highly Welcomed.We Made A lot For Our Customers.

How to process a Sample order?

Pls Confirm With Us The Modle You Need. and we will caculate total cost with shipping cost. And The Sample Fee Will Be Refunded In Bulk.

Sample Lead Time?

Sample Will Be Send Out Within 2-5days After Receiving Payment

Do you check quality before shipment?

100% QC Before Shipment.If There’re Some Unexpected Problem Happan,Like Quality Problem.

Lealso Exhibition

2023 Asia Adult EXPO(Hongkong)

2019 HongKong International Adult Sex toy Exhibition

2017 AEE Adult EXPO

2014 Shanghai API EXPO